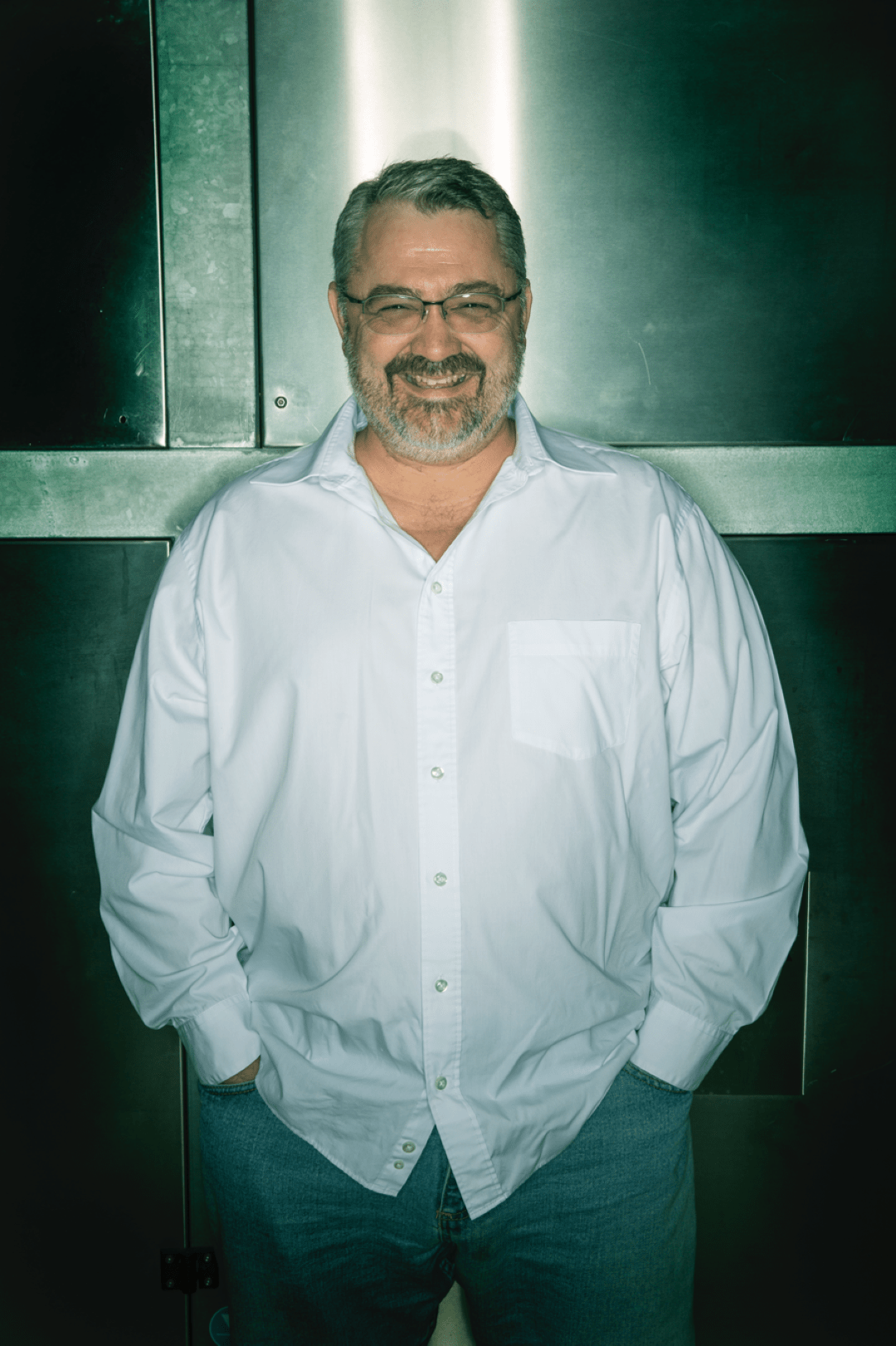

CEO

Roy Henderson’s background as a decorated combat officer in the South African Navy, together with his MBA, has given him the decisive leadership qualities to bravely lead Green Cell Technologies® (GCT®) from a start-up to where it is now, a successful global commercial entity. Razor sharp insight, coupled with a fair share of sheer bloody-mindedness and absolute belief in what he and co-founder Jan Vlok are doing, has kept them going and growing over the years. Success has not come without its challenges, and Roy’s leadership has also involved innovation, resilience, and digging deep to motivate the teams to continue.

By sharing his experiences and stories with other start-ups and entrepreneurs, Roy hopes to encourage others to not take “no” for an answer and to keep on going if their idea is sound and they believe in it. At the same time, to recognise and acknowledge whether the concept they have, should not progress, and to then fail fast to allow them to move on.

“For some, like us, we had no other choice, we had to keep going no matter what happened, but that was made easier by knowing that what we were ultimately developing and have now brought to fruition, can make the world a healthier, less environmentally stressed, and efficient place to be,” says the pioneering CEO. “We are always happy to engage with people and share our life lessons in growing this business and to assist where we can. But the biggest lesson we can pass on to those starting out on their business journey, is to love what they do, believe in themselves, and wholeheartedly commit.”

Application of the principles of war in the business world and a full range of leadership, have probably been the most important insights and experiences Roy has brought to his role as the leader of Green Cell Technologies®. In terms of the company’s culture, they have a straightforward approach to business built on honesty, integrity, and support – for one another, the partners, suppliers, and of course, their clients. This comes with a healthy amount of forthrightness, which for many people, is disarming at first.

This has led to a streamlined business approach that delivers fast results where and when needed. From the factory floor to the Board, everyone is accountable, know what the stakes are and that what they are doing is going to play a pivotal role in securing tomorrow’s future.

“The world is growing in population and the ability to feed and fuel it is taking strain, as processing methods have not really kept up or shifted in line with demand, or technology’s ability to effect real change,” adds Roy, who shares that one of the biggest challenges he and the company have faced, is being ahead of the curve, having a clear vision of what the manufacturing/processing industry needs and then convincing them of the capabilities of their “new” technology. This often requires a radical mindset shift in traditional approaches to manufacturing from the people making the decisions, something that is now rapidly coming up to speed as demand for more “natural” products grow.

GCT’s patented process, Dynamic Cellular Disruption® (DCD®), through its patented Disruptor® Technology, can process organic and inorganic matter. In organic matter, the technology can isolate certain ‘actives’ as required, and reduce them to a molecular level without the need for harmful heat or chemical intervention. This, therefore, does not alter or denature the molecular make-up of the original cell content. Further, the use of the DCD® process ensures stabilisation of the ‘active’ and preserve its integrity and nutritional values. Extracting and reducing to a nano level allows for the creation of other products besides the traditional pill/tablet format. These include but are not limited to water soluble powders or in a water disbursable format for use in smoothies, bars, creams, juices, etc.

To optimise the engineering of their Disruptor® technology, the company has utilised cutting-edge modellin software to improve the construction of Disruptor® Technology. Currently, they are in an expansion phase and growing Green Cell Technologies® international footprint with new offices and manufacturing facilities, with another centre of excellence, which will require the latest secure communications packages as well as manufacturing technologies.

“Our business is to build and license our technology to processing facilities within the food and beverage sector, cosmeceutical, nutraceutical, and pharmaceutical industries as well as agrichemicals and earth and animal husbandry sectors and biofuels,” explains Roy. “The world has a problem, in as much as it doesn’t necessarily have a shortage of raw materials but rather, inadequate processing solutions that have led to a waste problem, waste that still has value.”

The technology has multiple benefits for these industries, including but not limited to; increasing yields and efficacy of the processed materials; reducing waste or enabling zero waste in the processing; beneficiating existing waste streams; reducing micro and pathogens in food products; reduction in energy utilised to produce goods as the extractions are instant. There is no need for harmful heat or chemicals to be used in the processing phase; thus, there is little to no denaturing of the processed organic material.

From making molecular food emulsions and juices, whole wines and instant beers, whole kelp natural fertilisers, to extracting precious metals from mine dump tailings, and everything in between, Green Cell’s solution is versatile next generation extraction technology for the 4th Industrial Revolution.

For example, Green Cell Technologies® work with one of the world’s largest orange juice manufacturers, where Disruptor® technology is being deployed to process waste pulp. This can then be added back to the juice to make a whole fruit juice concentrate or added into a ‘not from cocentrate’ stream, used on its own as a smoothie, or dried into a fruit fibre that can be used as an ingredient into food and beverage as a thickening ingredient that does not carry E-numbers. The Disrupted orange waste pulp can also now be used to infuse other food products such as fruit, vegetables, and other fortifications.

Other examples are tomato sauce where the entire tomato is used – skin, seeds, and pulp. There is no waste. Botanical extractions with higher yields and greater purities, for instance, the hemp and CBD industry where wet and dry source material can be used to produce oil extraction and fibres for industrial and/or food use. Disruptor® technology has also been successfully used to process 4th and 5th quarter meat cuts to enhance nutrition and product viability.

Disruptor® technology and its process, Dynamic Cellular Disruption®, achieves a truly circular and inclusive economy without costing the earth. “We are in a very exciting phase at present, with the establishment of another centre of excellence to service our European and North American clients. Our Cape Town unit has been very successful in trialling all manner of materials for clients and even producing for them, and our European operations are set to do the same,” elucidates Roy. “As part of the service we offer, we also work with our clients on new product developments, which is exciting and has led us to developing further technologies that we are currently in the process of patenting. The world as we know it is constantly evolving, with technology playing a bigger role than ever.”

" The world has a problem, in as much as it doesn’t necessarily have a shortage of raw materials but rather, inadequate processing solutions that have led to a waste problem, waste that still has value. "

Roy Henderson, CDR (retired) NC+bar, NMM, MBA

CEO

© THE CEO PUBLICATION 2021 | All rights reserved. Terms and condition | Privacy and Policy